Choosing a lifting column often looks simple on paper—until accuracy, synchronization, and long-term stability start affecting real-world performance. In practical engineering projects, the decision between a DC lifting column and a servo lifting column frequently determines whether a system runs reliably for years or becomes a constant source of recalibration and downtime.

From ergonomic furniture to medical equipment and industrial automation, both solutions are widely used—but for very different reasons. In this article, we explain the core technical differences between DC and servo lifting columns without marketing language, helping engineers and buyers make a clear, application-driven decision.

What Is a DC Lifting Column?

A DC lifting column is a height-adjustable linear system designed for stable and cost-efficient vertical motion. It is commonly selected for applications where reliability and simplicity matter more than high positioning accuracy.

A typical DC lifting column consists of a DC motor, gearbox, lead screw, and a telescopic column structure that guides the load. Rotational motion from the motor is converted into linear movement through the lead screw, providing smooth and predictable lifting behavior.

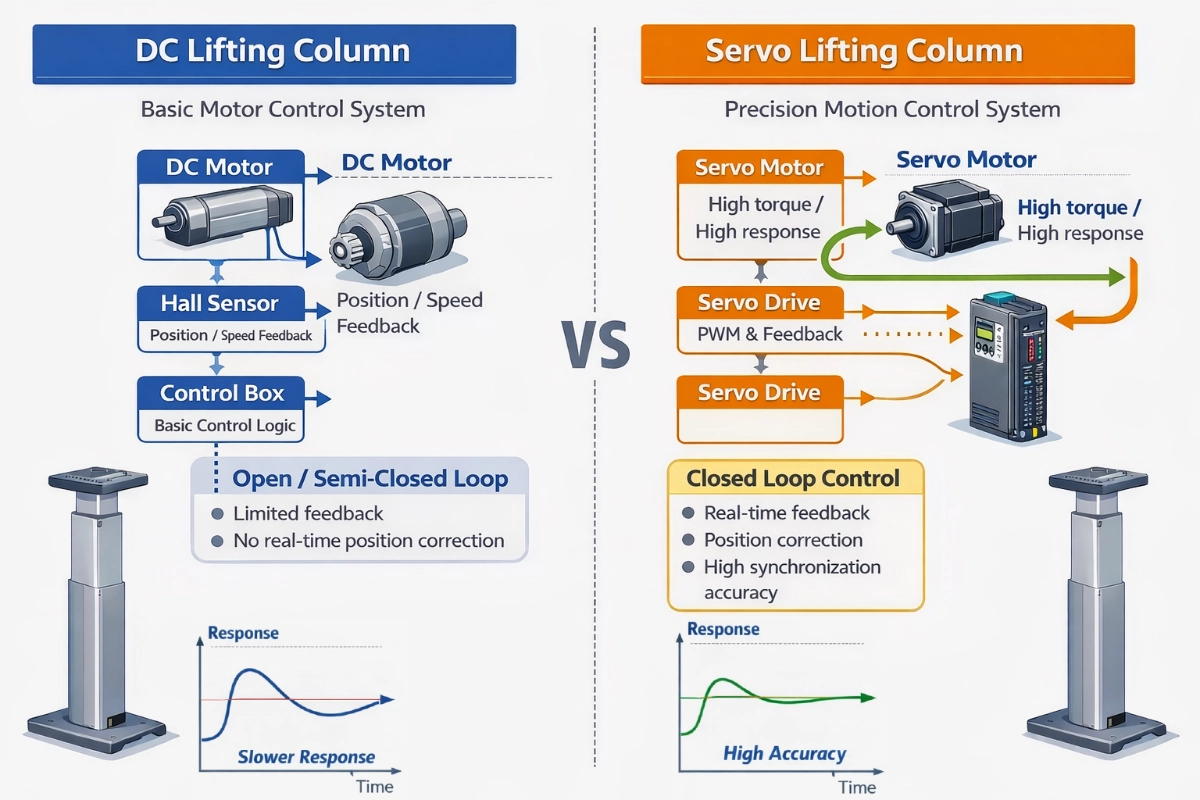

Most DC lifting columns operate in an open-loop or semi-closed-loop control system. Basic position feedback is often achieved using Hall sensors, which support functions such as height memory and simple synchronization. With moderate speed and millimeter-level accuracy, DC lifting columns are widely used in height-adjustable desks, basic medical beds, and light-duty adjustment systems.

What Is a Servo Lifting Column?

A servo lifting column is designed for applications that require high positioning accuracy, repeatability, and controlled motion. It is typically used where precise movement directly impacts system performance or safety.

Structurally, a servo lifting column integrates a servo motor, encoder, gearbox, and a rigid telescopic column. Unlike DC systems, servo lifting columns operate in a closed-loop control architecture, where real-time feedback continuously corrects position and speed.

This enables consistent motion under varying loads, precise positioning, and accurate multi-column synchronization. As a result, servo lifting columns are commonly applied in medical imaging equipment, automated production systems, laboratory platforms, and other high-precision industrial applications, where control accuracy outweighs system simplicity and cost.

DC vs Servo Lifting Column — Technical Comparison

With the basic architectures defined, the practical differences between DC and servo lifting columns become clearer when comparing how they behave under real operating conditions.

Control Method and Feedback System

DC lifting columns typically rely on open-loop or Hall-sensor-based feedback systems. Hall sensors generate pulse signals that estimate position based on motor rotation, but they do not correct deviations in real time.

Servo lifting columns use encoder-based closed-loop control, continuously comparing commanded motion with actual position. This allows the system to detect and correct deviations instantly, reducing cumulative positioning errors throughout the lifting cycle.

Positioning Accuracy and Repeatability

DC lifting columns generally provide millimeter-level positioning accuracy, which is sufficient for many furniture and general medical applications. However, accuracy can vary with load changes and long-term wear.

Servo lifting columns offer significantly higher repeatability. Closed-loop control ensures that the same target position is reached consistently over long operating cycles, making them suitable for precision-dependent systems.

Speed Performance Under Load

DC lifting columns may experience speed variation when load conditions change, especially in systems without advanced compensation mechanisms.

Servo lifting columns maintain consistent speed under varying loads, as the controller dynamically adjusts motor output to match the commanded motion profile. Stable speed control improves system predictability and coordination.

Load Stability and Vibration Control

DC-driven lifting columns rely mainly on mechanical structure for stability. At extended heights or under uneven loads, small vibrations or deflection may occur.

Servo lifting columns benefit from active control combined with structural stiffness, enabling better vibration suppression during acceleration and deceleration. This is particularly important for sensitive equipment and precision platforms.

Noise and Motion Smoothness

DC lifting columns generally provide acceptable noise levels for office and medical environments, though audible changes may occur during start-stop transitions.

Servo systems allow smoother motion profiles with controlled acceleration and deceleration, reducing mechanical shock and improving perceived quality, especially in quiet or shared environments.

System Complexity and Integration

DC lifting columns feature simpler wiring and control logic, resulting in faster integration and shorter commissioning time.

Servo lifting columns require more complex system integration, including servo drives, encoder wiring, and parameter tuning. Commissioning typically demands higher technical expertise.

Cost vs Performance Trade-Offs

DC lifting column systems have lower initial cost and simpler installation. They are well suited for cost-sensitive applications with moderate performance requirements.

Servo lifting columns involve higher upfront investment but deliver superior accuracy, stability, and controllability. In performance-driven systems, these benefits often outweigh the added complexity over the system’s lifecycle.

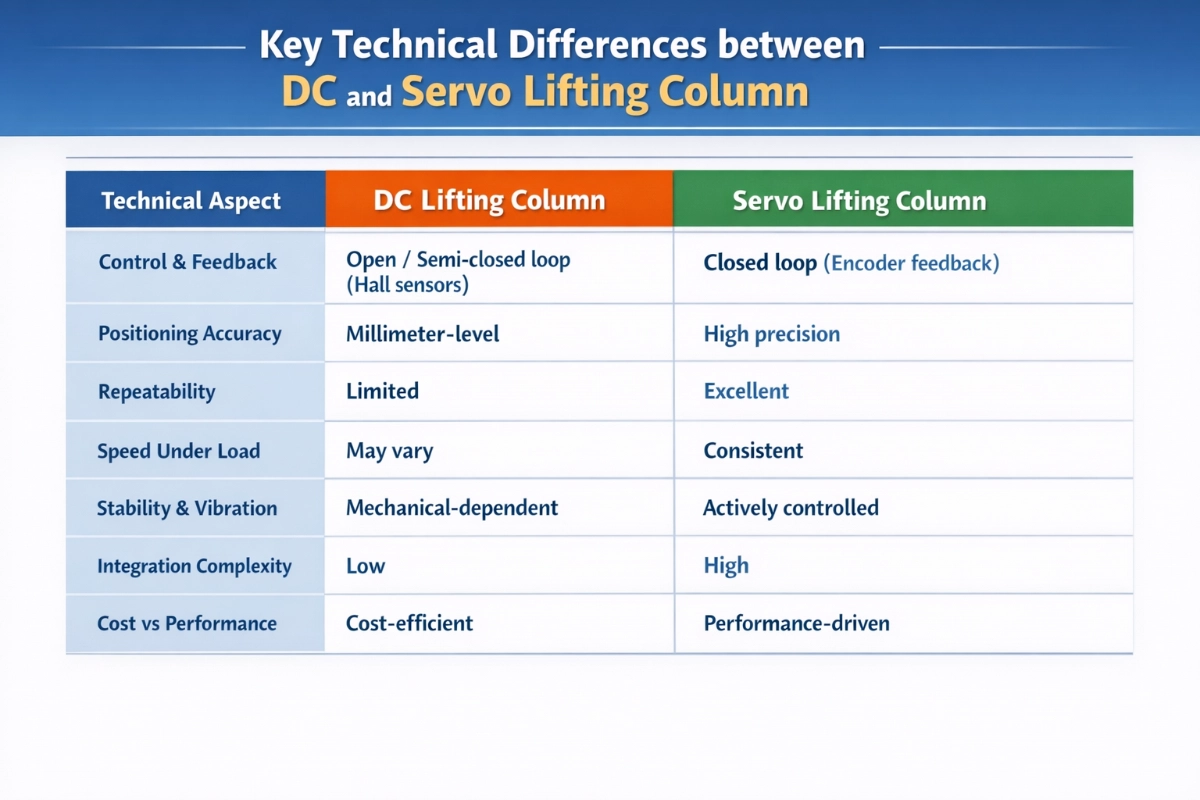

Summary Table: Key Technical Differences

For a quick reference, the table below summarizes the key technical differences discussed above.

How to Choose Between a DC and Servo Lifting Column

Choosing between a DC and a servo lifting column should start with a clear understanding of what level of control the application truly requires.

If the primary goals are cost efficiency, simple integration, and reliable vertical motion, a DC lifting column is often the most practical choice.

A servo lifting column becomes technically justified when precise positioning, high repeatability, or consistent motion under varying loads is required. Applications involving sensitive equipment or coordinated motion benefit significantly from closed-loop servo control.

A useful rule of thumb is to define accuracy and synchronization requirements first. Once those boundaries are clear, the appropriate lifting column type usually becomes obvious.

Conclusion

Ultimately, choosing between a DC and a servo lifting column is less about technology labels and more about understanding what the application truly demands.

DC lifting columns and servo lifting columns are not competing technologies—they address different engineering needs. DC systems offer simplicity and cost efficiency, while servo systems deliver precision and advanced control.

The most reliable selection approach starts with understanding application requirements rather than chasing specifications. When accuracy and control matter, servo lifting columns justify their complexity. When they do not, DC lifting columns remain a proven and efficient solution.